Few robotics categories are poised to benefit more from the events of the past year than construction. It’s a booming field that could benefit massively from automaton, a fact that’s only been amplified as the pandemic brought many nonessential businesses to a standstill. We’ve seen a number of players in the category raise notable rounds over the past year or so, including Toggle, Dusty, Scaled and SkyMul.

Founded in 2018, Houston-based Rugged Robotics raised a $2.5 million seed round back in 2019. While the company isn’t actively raising at the moment, it has already begun to roll out its technology in early pilots, including a partnership with Massachusetts-based construction-firm Consigli.

Image Credits: Rugged Robotics

“We had a client that was pretty progressive looking,” said Consigli’s Jack Moran. “It’s a building where we were controlling the core shell of the project, as well as the fit-out, which was pretty complex — lots of odd shapes that would be a challenge for us.”

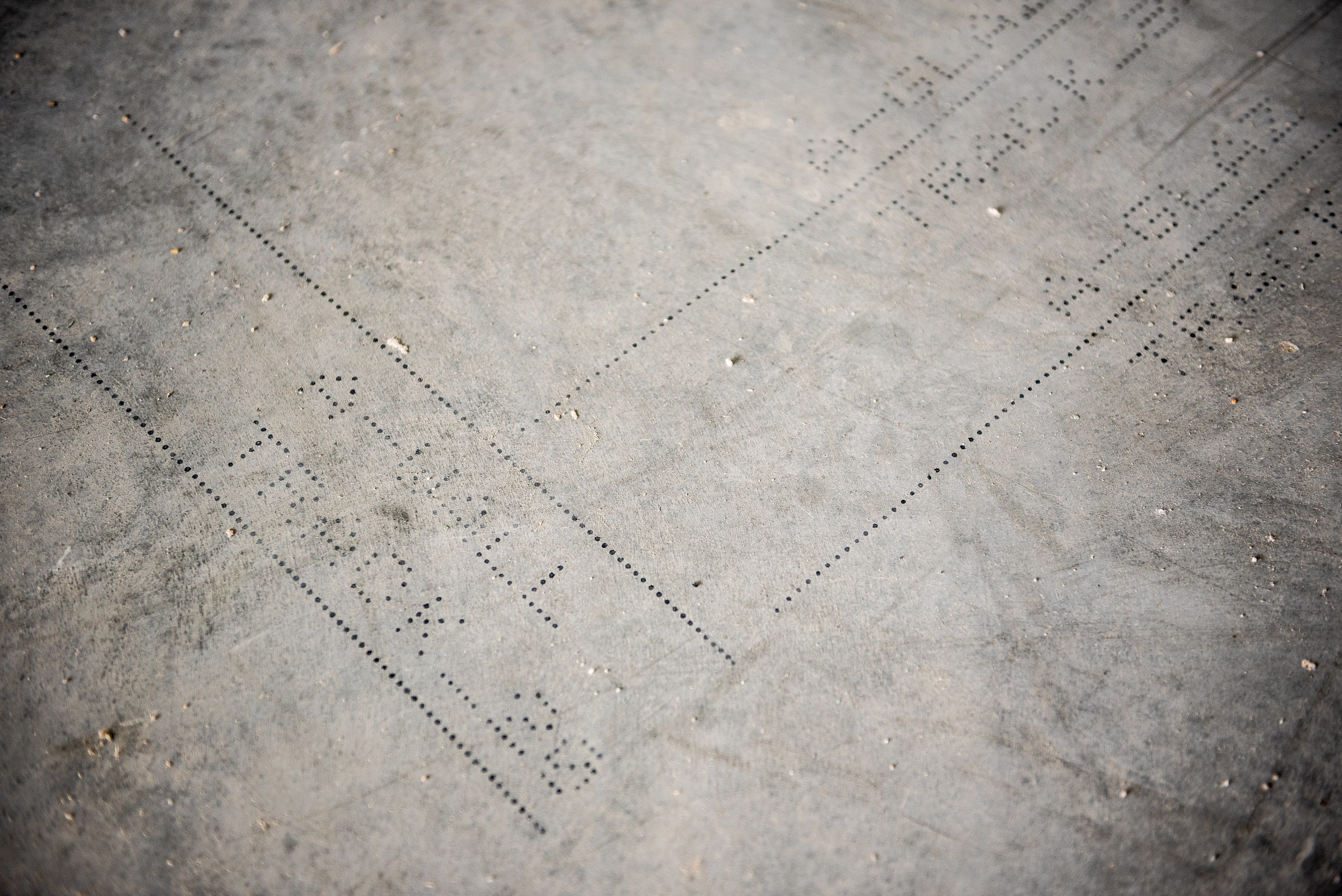

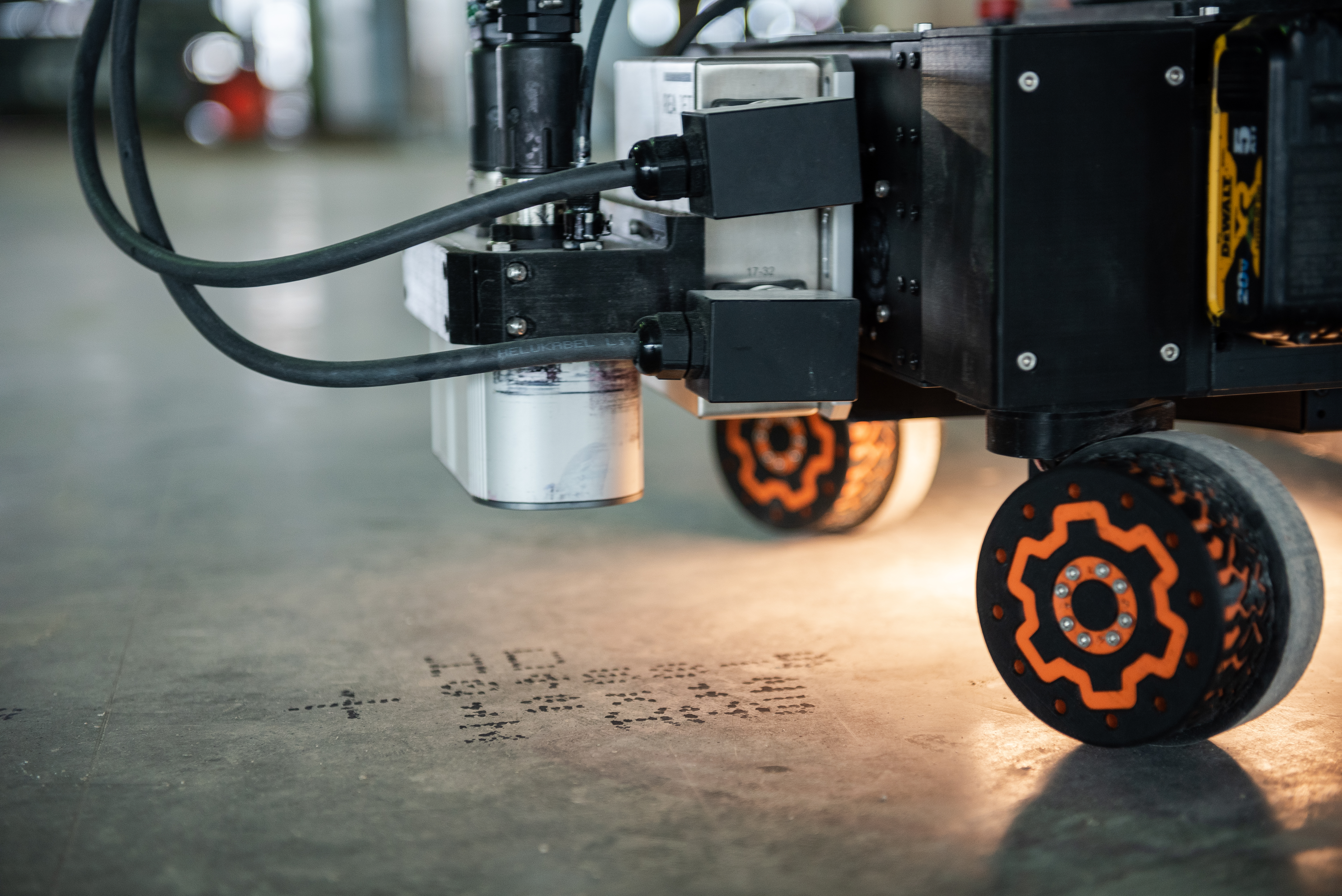

Rugged’s self-described “layout Roomba” was used to help build a 10-story building in Cambridge, Massachusetts, effectively drawing blueprints on the ground of the space that amounted to around 40,000 square feet per floor. The partnership effectively finds Rugged taking a key step from its early research and development mode to commercialize.

“The layout process is the most important task in the construction process,” Rugged founder and CEO Derrick Morse said in an interview with TechCrunch. “Marking where things are installed defines where things are built. A mistake made during layout trickles into the overall construction process and it results in rework, delays and additional expenses.”

The team is still small, with a headcount of around six full-time employees, including co-founders with backgrounds at NASA and Samsung. The team currently has three robots, with plans to expand to five. They print dot matrix ink patterns on the ground to give construction teams a real-world orientation for the buildings they’re creating.

Image Credits: Rugged Robotics

A member of the Rugged team travels to the site with the robot to supervise the robot as it executes on its plans, with the startup charging the construction company through a RaaS (robotics as a service) model.

“We have insatiable customer demand,” said Morse. “We have several multibillion-dollar contractors that are excited to do pilots and demos with us. We’ll be growing the organization and fleet in the upcoming 12 months, and we’ll likely be bringing in additional capital to enable that growth.”